Wood surface treatment has traditionally relied on sanding, chemical strippers, and abrasive blasting. While effective, these methods can damage wood fibers, generate dust, and involve toxic chemicals.

With the rise of laser technology, many manufacturers are asking: does laser wood stripping really work?

This article examines the efficiency, limitations, and industrial use cases of laser wood stripping machines, helping manufacturers and restoration professionals make informed decisions.

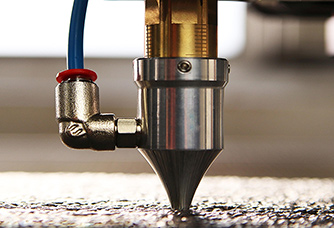

Laser wood stripping uses controlled laser energy to remove paint, varnish, resin, or surface contaminants from wooden substrates. The laser selectively targets coatings without deeply penetrating the wood, preserving its natural structure.

The process is non-contact, which significantly reduces mechanical stress on the material. This makes laser stripping especially suitable for delicate or high-value wood products.

For industrial applications, laser stripping offers consistent results across large batches of wooden components. While sanding speed depends on operator skill, laser systems deliver repeatable performance.

Laser-treated wood surfaces maintain clearer grain patterns and smoother textures. This is particularly valuable for furniture manufacturing, musical instruments, and architectural wood elements.

Because the laser does not gouge or over-strip the surface, less reprocessing is required. This leads to higher overall productivity.

Manufacturers use laser stripping to remove old coatings during refurbishing or before refinishing premium furniture.

Historic wood structures often require gentle cleaning. Laser technology removes layers of paint while preserving original craftsmanship.

Laser systems allow selective stripping in specific areas, supporting customized designs and decorative finishes.

Laser wood stripping is not a one-size-fits-all solution. Highly charred surfaces or thick multilayer coatings may require multiple passes. Initial equipment investment is higher than manual tools, but long-term savings offset the cost.

For industrial and professional users, the answer is yes. According to real-world evaluations, laser wood stripping machines deliver superior surface quality, safer working conditions, and lower operating costs over time.

If you want a deeper technical evaluation, read more at: does the laser wood stripping machine really work.

Laser wood stripping is a proven and efficient technology for modern wood processing and restoration. Its precision, safety, and repeatability make it a valuable asset for industrial applications that demand quality and consistency.

We use cookies to ensure you get the best experience on our website. Read more...