Jindal Steel has reshaped India’s steel manufacturing landscape by becoming the country’s largest heat treatment player, expanding its monthly heat treatment capacity to 60,000 tonnes from about 20,000 tonnes earlier.

This move not only strengthens Jindal Steel’s manufacturing base but also marks a big step in reducing dependence on imported premium steel products.

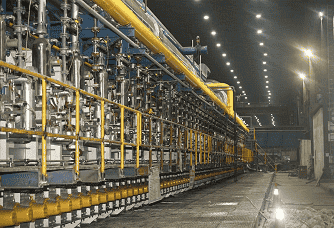

The company’s upgraded heat treatment facilities now handle a wide range of steel plates in furnace normalized (FN) and quenched & tempered (Q&T) categories. These plants can process plates from 6 mm up to 200 mm in thickness and up to 5 meters in width, using advanced temperature control technology to ensure uniform quality.

This enables Jindal Steel to produce high-strength plates with over 2,000 MPa, abrasion-resistant plates above 600 BHN, defense-grade plates with guaranteed ballistic performance, and specialized tool, die, and alloy steels that were previously imported.

Also Read: Major Trends Influencing Demand for Custom Steel Castings in India

Speaking on the expansion, S.K. Pradhan, Head of Flat Products at Jindal Steel, said, “High-quality heat-treated plates manufactured by Jindal Steel are playing a pivotal role in strengthening India’s industrial competitiveness.” He added that this capacity increase helps Indian manufacturers across infrastructure, engineering, energy, and heavy machinery sectors meet stringent global standards.

On an annual basis, this expansion means Jindal Steel has tripled its heat-treated plate capacity to about 7 lakh tonnes, underlining its strategy to support domestic manufacturing goals and boost export potential across global markets.

The company’s broader product portfolio now caters to infrastructure, shipbuilding, construction, oil and gas transportation, and defense applications. By scaling up this critical segment of production, Jindal Steel reinforces its position in the Indian steel industry, aligns with self-reliance goals, and strengthens India’s supply chain for advanced steel products.

We use cookies to ensure you get the best experience on our website. Read more...