India’s focus on infrastructural development is fueling the geosynthetic materials sector. Simultaneously, factors like technological advancements and regulatory transformations are also expected to shape the industry’s future. However, challenges like budgetary restrictions and timely deliveries, exacerbated by volatile global markets, poor site preparation, improper material handling, and inadequate installation techniques compromise performance and hinder client success. As a leading provider of geosynthetic products curated meticulously, Megaplast India Pvt. Ltd., addresses the critical challenges in this space through a series of structured measures.

Committed to resolving the challenges faced by customers, Megaplast India takes proactive steps like ensuring rigorous site assessments, and carefully handling material to prevent damage during storage and transport. The firm further prioritizes supporting installers with specialized tools for efficiency and precision in installing equipment, along with organizing comprehensive training programs, and extensive quality control measures. Through a unique blend of diverse practices, the firm ensures superior performance, standing out as a preferred partner.

Innovating Future-Ready Products

Armed with an exceptional experience in the sector, spanning over ten years, Megaplast India is innovating products that serve future-ready aspirations of a diverse range of industries. The company manufactures geomembrane sheets of various kinds that can be utilized in diverse applications. The firm’s offerings are widely used in embankment dams, tunnels, water resources, aquaculture, waste management, oil & gas, mining, and coal, as well as packaging materials and films, allowing the firm to serve many diverse industries. The company is also pioneering EVOH-based barrier products that offer nearly zero percent permeability, addressing unmet needs in VOC containment and environmental protection.

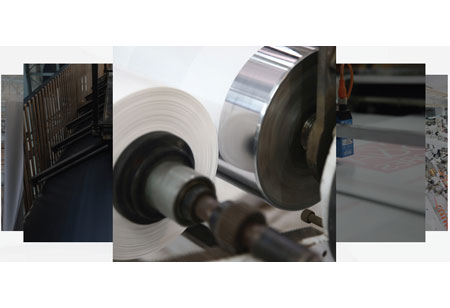

Supporting the firm’s expansion across sectors is its robust innovation center that focuses on R&D for the creation of efficient and cost-effective solutions. The capabilities are further supported by the firm’s state-of-the-art equipment, such as its 7-layer extrusion lines. Such infrastructure also plays in favor of promoting sustainability by minimizing manufacturing waste and optimizing the production processes.

“Our commitment to unmatched safety, environmental management, and product excellence with certifications like GAI-LAP, CE, NABL, ISO 9001, and ISO 45001 ensures that our products consistently meet the highest global standards”, shares Gaurav Jain, Director, Megaplast India.

Committed to providing the best quality products, the organization is strengthened by a stellar team of polymer scientists, who strive to innovate unique blends of polymers that help the company design products aligned with the distinctive needs of its varied clientele while also being future ready. Building durable as well as flexible products that are competitively priced, the company gains its competitive edge by prioritizing product quality through continuous investments in advanced technology.

Tailored Solutions

By applying advanced forecasting methods and market analysis techniques, Megaplast India proactively predicts market needs for every sector to which it caters. Using this intel, and its multiple production lines, the firm ensures on-time delivery of bulk orders. Its organized methods for segmenting raw materials and equipment using schedules enable it to masterfully cater to the diverse sectoral needs, while ensuring customization for optimal performance.

In facilitating this ability to tailor products, while maintaining top-notch quality and ensuring precision, technology plays a pivotal role. Technology’s integral role in the geosynthetics industry for the production of advanced products that meet rigorous performance standards in diverse applications cannot be overstated.

At Megaplast India, advanced machinery, continuous R&D, and rigorous testing protocols are embraced from the start. The entire process from raw material selection to storage, handling, and installation techniques is technology powered. It also enables the firm to stand out by ensuring zero defect products.

“Megaplast India stands out for its commitment to zero defect products and continuous investment in advanced technology. Our 7-layer extrusion equipment and state-of the-art innovation centre exemplify this commitment”, adds Gaurav.

With decades of expertise in manufacturing geosynthetic products, Megaplast India has grown into a leader, manufacturing a diverse range of products from its 3,00,000 sq.ft manufacturing floor space. The manufacturing facility is fitted with the latest, technologically advanced machines that boast a production capacity of over 24000 metric tons of products per year.

Megaplast India has solidified its position as a leader in the geosynthetics industry, proudly standing as a trusted partner for geosynthetic products and solutions

The firm has segregated manufacturing capabilities, with its geomembrane and polyethylene film production plant setup in Daman. Through this segregation, it effectively controls production conditions, which results in higher quality products and competitive production costs.

The firm is further strengthened by its elaborate workforce of over 600 and enjoys a leading position as a top exporter across 20 countries. Leveraging European technology, the firm is the first of its kind to manufacture the 8-metre-wide geomembrane which finds specialized and vital application in critical sectors.

“We strongly believe that there is no organizational success without our people, thus looking after our people is indispensable. As a team, we work together to achieve optimum utilization of available resources for innovation and continuous improvement in product quality which allows us to consistently produce the best products”, further adds Gaurav.

Client-Centric Services

A nationally accredited company, Megaplast India has repeatedly been recognized for its excellence in manufacturing, as well as its prompt client service. Since client satisfaction is a core philosophy and business value at Megaplast India, the company has implemented a structured approach and strategies to ensure every concern is proactively addressed.

To address client queries, the company focuses on prompt responses within 24 hours. It also implements ISO-based service parameters, training its workforce to adhere to the prescribed techniques for effective solutions. A structured escalation process is utilized to resolve the diverse kinds of complaints and concerns at the right level.

In addition, detailed documentation of the grievances is maintained to identify repeated concerns from the root. The team also implements a robust feedback procedure in the production briefings which helps in improving processes, thereby ensuring that clients do not face the same challenges again.

Building Future Strategies

Under the guidance and leadership of Gaurav Jain, Megaplast India has carved a unique and distinguished position for itself in a highly competitive industry. Leveraging his learnings from his dual degree courses from the University of Pennsylvania, including the Bachelor of Science in Economics with specialization in finance from The Wharton School and Bachelor of Science in Engineering with a major in Computer Science from The School of Engineering and Applied Sciences, he has shaped the firm’s strategic path.

Since its inception, the company has achieved a string of impressive milestones, such as becoming one of the top global players in the industry to have advanced manufacturing capabilities. Through a proven record of delivering value driven products consistently, the company has also earned a place of high repute and trust among its customers, developing a loyal client base worldwide.

Gaurav concludes, “We are proud to be recognized as a leader in the geosynthetics industry and remain dedicated to advancing sustainable solutions for our customers”.

Working towards a robust future, the company’s key strategies for advancement are focused on innovation and addressing unmet industry needs. The firm is also working towards agricultural solutions. Prioritizing sustain ability, Megaplast India is dedicated towards developing products that are customer-centric and environmentally friendly.

We use cookies to ensure you get the best experience on our website. Read more...