Ministry of Electronics and Information Technology (MeitY), in association with India Cellular & Electronics Association (ICEA) recently unveiled a five year roadmap and vision document for the

electronics industry, vowing to catapult the manufacturing output from the current 75 billion USD to 300 billion USD by 2026. It was the second volume of the two-part vision document, following the first one that was released in November 2021. As per the roadmap set in the vision document, the ministry has outlined some of the key products that would lead to the growth in

electronics manufacturing.

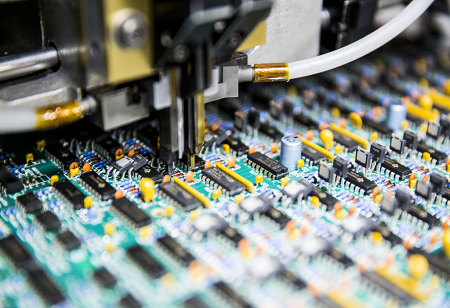

The list includes mobile phones, IT hardware, consumer electronics, auto electronics, electronic components, LED Lighting, PCBA, wearables and telecom equipment, to name a few. Mobile manufacturing is expected to comprise 40 per cent of the ambitious growth projection. “As an important part of the trillion dollar digital economy of electronics manufacturing, we continue to handhold the industry, shepherd them and bring in more and more players into the electronics ecosystem,” said Rajeev Chandrasekhar, MoS, Electronics & IT to Economic Times.

Considering the fact that the electronics industry in India grew three-fold between 2014 and 2020, the goal set by MeitY does not seem far-fetched and is totally achievable. However, the path leading to the target is fraught with a unique set of challenges. Let us delve into the challenges and see if they are surmountable.

Undue Focus on Assembly

On the core manufacturing side, the electronics industry in India seems to be in dire straits. Getting most of the components imported, the manufacturing facilities have been reduced to mere assembly units. Close to 80 per cent of the components comprising processors, cameras, and memory chips are being imported. Consequently, the net value addition by production units is paltry 5-15 per cent. This is because in electronics manufacturing, most of the value-adding processes are executed before assembly stage.

So, the need of the hour is to start building the foundation for ultimate competence in electronics manufacturing. The first and foremost thing to do is setting up of semiconductor fabrication plants to produce microchips. In India, these fabrication plants are only present at Indian Space Research Organization (ISRO) and the Defence Research and Development Organization (DRDO) with their use only meant for space and defence systems.

Setting up the foundries is a challenge as it demands huge capital expenditure. The domestic players have so far refrained from venturing into this field owing to their incapability to compete with the global behemoths in this area.