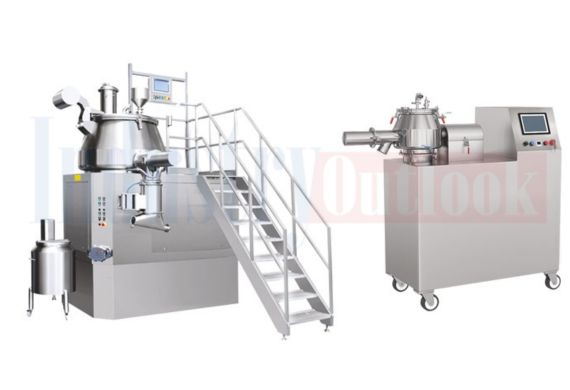

7. Granulators –

Granulation is the mechanism of converting small powder particles into bigger, uniform granules by bonding them either through the application of pressure or through a binding agent. In pharmaceutical applications, such granulation has to be done since it fosters the powder flow, thereby making the filling of tablets or capsules easier and more accurate. Also, granulation increases compressibility, guarantees uniform distribution of active ingredients, and diminishes dust, thereby reducing contamination hazards.

Granulation procedures include wet, dry, and melt granulation. These granulation procedures are handled by high shear, fluid bed, low shear, oscillating, and single-pot granulators. As the demand for oral drugs keeps growing, the need for an efficient granulation machine in pharma production also rises.

We use cookies to ensure you get the best experience on our website. Read more...